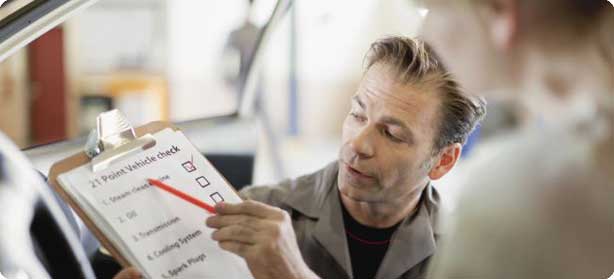

Inspection services have been in process for decades now to ensure only best products reach the market. Over the time, the work procedure has obviously undergone several changes. These changes have been primarily brought about by technology over the last couple of years.

Evolving trends for the better is a necessary change that every industry must experience. But this does not indicate that there are no flaws or mistakes in the processes. Unfortunately, certain mistakes still exist in the inspection process that needs to be rectified and stopped immediately. Inspection companies while drafting their list of services and ways of executing them need to avoid the following mistakes.

- Confusing Product Specifications with Product Inspection – Specifications are usually provided by the clients to the third party inspection companies. However, professional inspectors should not confuse product specifications with their inspection procedures. The inspection process should be independent of the product specifications. In the course of inspecting the products, the specifications should be met. Clarity about the requirements is important but that should not influence your inspection protocol. Rotating inspectors are the best format to ensure effective quality control is followed.

- Using Improper Equipment – There are certain equipment that all factories need to have and offer the same to the quality control inspectors. The factory needs to have adequate infrastructure helping the inspection process. This does not indicate that the inspection company is not responsible for bringing their own specialized equipment for on-site product testing. The third party inspection companies should refrain from making this mistake and carry their specialized equipment. Failure on the part of inspectors to bring proper equipment leads to inaccuracy in the testing of the products.

- Not Allowing Factory Representative to Influence Reports – The factory representative is accountable for the production process that takes place in the factory. In case the quality control team finds fault in the product, the factory representative is held responsible for it. There have been instances when the factory representative has tried to influence reports in case they were not favorable. This is a practice that needs to be stopped and influencing reports should be prevented at all costs. Reports filed by inspectors need to be kept away from the factory representative so that the recorded data is not tampered with.

- Using Wrong AQL Sample Size – Quality inspectors are given specific AQL levels that determine the sample size which needs to be inspected. Inspectors need to calculate and read the sample size in the correct format. Failing to do this will affect the product testing results. The wrong details will lead the quality inspector to, take a smaller inspection sample than the sample which was pre-decided will increase chances of missing out defects.

- Putting Incorrect Photos in the Inspection Report – Professional and comprehensive quality control reports include images of the products that were examined. Many third party inspection companies fail to include images and that is where they go wrong. Failing to offer appropriate images lead to confusion in identifying the defects. Having the data recorded is necessary but providing the images alongside help employees to understand defects in a better way. So make sure you always add images and make the report a lot more detailed.

These are some of the common mistakes that most third party inspection companies do. So make sure you refresh your inspection policies by avoiding these mistakes.